What Is MRP?

The 3 Main Tools of Manufacturing Resource Planning

What is MRP? That’s a surprisingly nuanced question.

In broad strokes, MRP is the earliest computer-based inventory management method, designed to improve productivity. It’s a collection of techniques and practices that allows manufacturing businesses to predict their future inventory state and schedule key actions accordingly to optimize it.

The initials MRP actually refer to at least two related but distinct categories of software systems: the older, simpler “Material Requirements Planning” and the more robust “Manufacturing Resource Planning” (also called MRP II).

Questionable naming decisions aside, any MRP system (from either generation) is built on the foundation of three basic tools.

The 3 Tools of Any MRP System

MRP systems (like their more broadly useful relatives, the ERP systems) are, at their core, analytical tools.

In a modern MRP system, that analysis can include detailed forecasts of requirements and sales well into the future. But no matter how psychic a certain MRP product seems, all the information it gives you is extrapolated from the same 3 inputs.

Those are the master production schedule, bills of materials, and the inventory status records. They might go by slightly different names depending on the system, but they should be easy to identify.

In plain language, they keep track of what you need to make, what it takes to make it, and what you have on hand.

Master Production Schedule

The master production schedule (MPS) is a detailed schedule describing what you will produce and when.

The process of generating the MPS can include many input factors. In a simple scenario, the MRP system might just note all incoming orders, schedule the ordered products to be assembled at the first available opportunity (depending on your production capacity), and update the schedule when new orders come in.

In a more optimized system, demand forecasts will be generated and used to schedule production long before the associated orders even come in.

And, of course, any good MRP system will do as much as is feasible to account for lead times and minimize the time between your customer placing an order and receiving their goods.

Bills of Materials

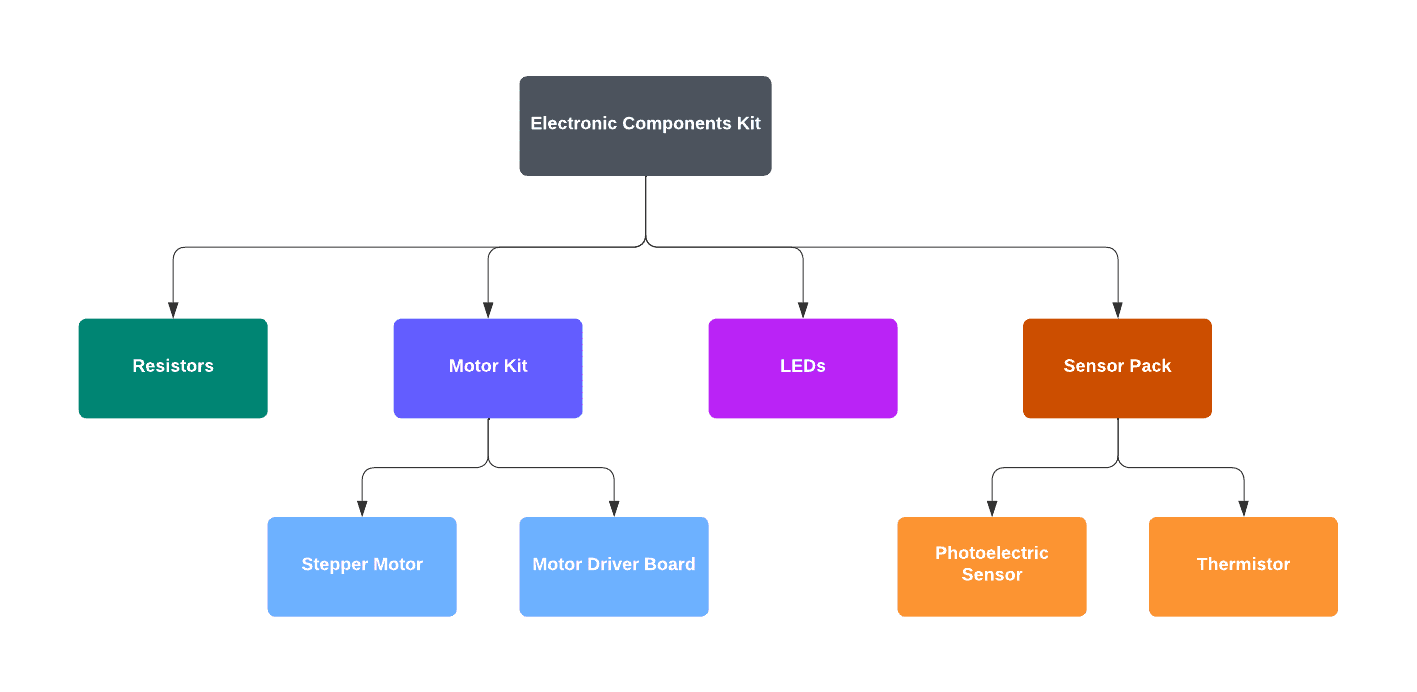

For each product you offer, you’ll enter a bill of materials (BOM) into the MRP system.

A BOM is basically just a list of all the components needed to make the specified product, except that it’s hierarchical.

That is, if you have to produce one or more sub-assemblies before you can put together the finished good that you actually sell, the components of the sub-assemblies will also be listed. The BOM lists all those components and which sub-assemblies they belong to.

And if the sub-assemblies have sub-sub-assemblies, you can keep going. Just add as many layers you need until you get to raw materials (components that you source from outside your business).

Example bill of materials (BOM) for a hobbyist electronic components kit

Inventory Status Records

This is the topic for an entire article of its own. (Several, in fact.)

The short version is that an MRP system will have a detailed set of records of what you have in your inventory at present. This includes raw materials, work-in-process (WIP), finished goods, and more.

These records are updated frequently and serve as a starting point for the master production schedule to plan from. The MRP system will notice when you’re running low on any particular components and alert you to reorder them, and it will allocate items from the inventory status records to individual builds.

Does Your Business Need MRP?

If an MRP system sounds like it would be useful for your business, but you want a more unified, company-wide system with accounting functionality, sales applications, and more, you’re probably looking for ERP (enterprise resource planning).

Nearly any ERP system will have all the essential MRP features, but that’s just the tip of the ERP iceberg.To find out how AcctVantage ERP can support your ongoing business growth and success, click here to get in touch with us.